Part of a Series on Solar Cell Production

Monocrystalline and polycrystalline silicon are the industry leaders for photovoltaic cell construction. Thin film technologies are catching up, however, as manufacturers start to develop roofing tiles, windows and other building products with solar cells built in. With these products, the building itself becomes the “solar panel,” allowing for a sleeker, more minimalist design. These flexible film solar cells may be manufactured with amorphous silicon, or one of the other thin film options presently available. At this time, Solaron does not install thin film photovoltaics. In this article we discuss how amorphous silicon is used to make a solar cell and why our company does not install these types of cells.

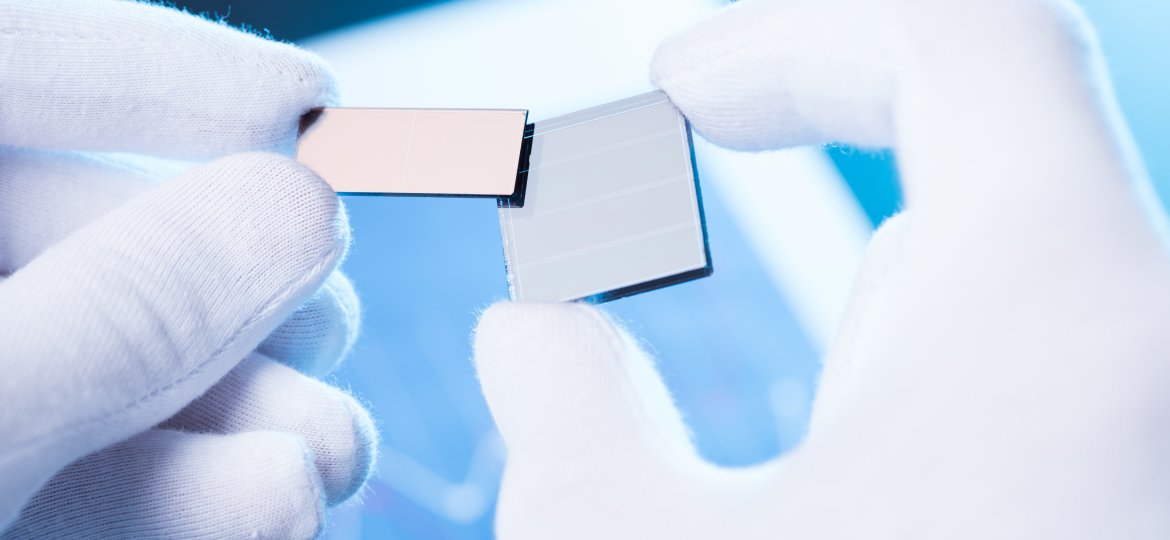

How to Make an Amorphous Silicon Solar Cell

Although various techniques may be used, one way to produce a thin film amorphous silicon solar cell starts with a substrate. This is a thin sheet of plastic. Amorphous silicon is deposited as a vapor on one side and a very thin metal layer is placed on the other. On top of the silicon layer, a transparent conductive material is laid down to guarantee the generation of a current from the individual solar cells. Laser beams etch out the margins of each solar cell. The entire product may then be encased in a clear, protective laminate. So from top to bottom, the thin film in this production model is made up of the protective laminate, transparent conductor, amorphous silicon, substrate, thin metal layer, and protective laminate. Additional wiring is added to create connectors for various electrical applications. Other methods are used, but all result in a very thin set of connected photovoltaic cells.

With monocrystalline and polycrystalline silicon, the atoms form up in an ordered structure. Amorphous silicon does not demonstrate this type of order. The silicon atoms are distributed randomly on the substrate. As a result, individual thin film solar cells are generally small and large numbers of them must be combined together to create a useful solar panel.

Advantages and Disadvantages of Amorphous Silicon Cells

On the plus side, amorphous silicon solar cells generally contain no toxic metals and are very lightweight. This makes them very useful in small electronics, other portable applications, solar electric fabrics and the aforementioned flexible building applications.